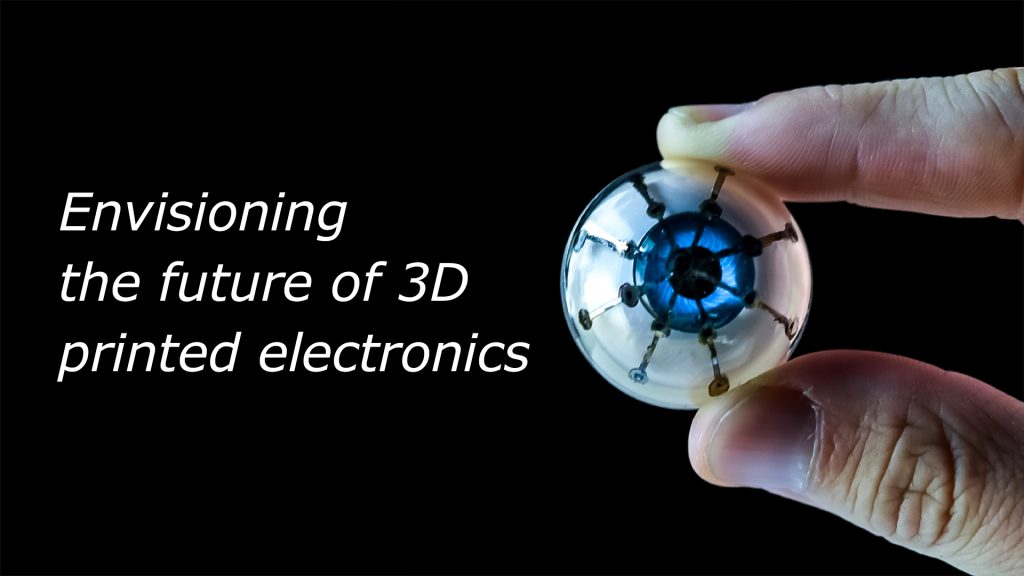

3D printing optoelectronic devices directly into curved structures could create a new paradigm for ocular prosthetics.

Introduction

Today, optoelectronic devices such as LEDs and light receptors (photodiodes) are everywhere, ranging in application from mobile phone screens and energy-efficient lighting to large digital display panels and image sensors. These devices – which convert electrical energy into light or vice versa– transmit a substantial amount of visual information. Made using the same techniques used to make computer chips, optoelectronic devices similarly get smaller and smaller as technology evolves, eventually coming into closer contact with human bodies (the now-omnipresent smartwatch, for instance). With this increasing proximity comes an increasing role in our lives; where we currently rely on wearable sensing and therapeutic devices to monitor our health, routine use of smart prosthetics in our skin, tissues, and organs is fast becoming a reality.

Yet, a major barrier to fitting these devices conformally – where they match the geometric properties of the surface onto which we apply them – is the variation between the device and the person’s body; one is flat and mechanically rigid, the other is three-dimensional and soft. A promising solution to this challenge is emerging as two key research areas intersect:

- the development of novel functional material ‘inks’

- 3D printing active devices at the micro-scale (about the width of a human hair)

Combining these, our group produced an optoelectronic device exclusively through 3D printing – no other fabrication equipment required. From here, we can (optimistically) foresee a future of electronics: printing electronic devices directly onto the human body – anywhere, at any time – for regenerative and health monitoring purposes.

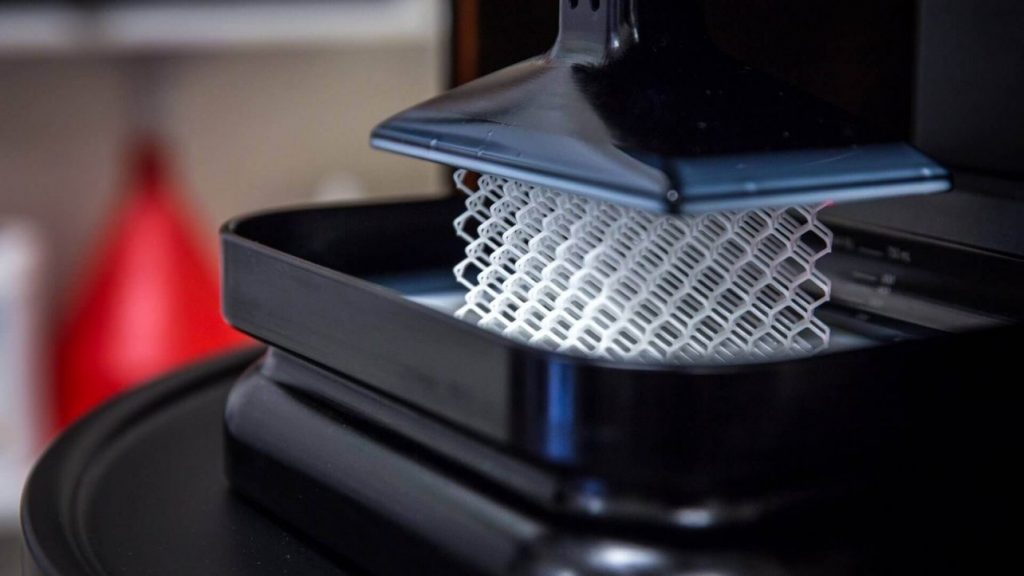

Fully 3D printed active electronics

3D printing is now commonly used to produce plastics, metals, and ceramics. But what about semiconductors, or active electronic devices? After all, silicon-based semiconducting electronics are now key components of modern life. Typically, semiconductors are produced in a cleanroom environment using techniques such as photolithography, material deposition, spin-coating, and etching. To move toward an entirely 3D printed method of manufacture, we need to select materials with good printability and formulate them into inks. The choice of materials is important; they have to be able to smoothly dispense and uniformly deposit into desired features.

Functionally, materials for the essential device components should exhibit:

- good performance and efficiency

- transparency (for optical devices)

- proper alignment of band structures and work functions among one another

- the ability to be printed layer-by-layer without disturbing previous layers.

A palette of materials that meets the above criteria is currently under development – gradually expanding to meet the requirements of entirely 3D printed electronics. As an example, LEDs require two electrodes through which electrical currents either enter or exit. We can 3D print both of these: we can print and thermally cure silver nanoparticles for one of the electrodes, and we can use a highly conductive liquid metal for the other. We could also use conjugated polymers, a class of organic semiconductors, to print charge carrier layers. As for the active layer, which converts photons to electrons (and vice versa), several materials are possible, including silicon.

Quantum dot LEDs

Quantum dots (QDs) are a class of semiconducting nanoparticles that are key to developing future optical (and electronic) devices. QDs can emit or sense light within very narrow spectra, spectra which we can manipulate by changing the size of the particles used. For example, the larger the particle we use, the redder the light; the smaller the particle we use, the bluer. As such, QDs are widely regarded as an important material for next-generation display technologies, because they produce pure monochromatic colors.

Recently, QDs containing cadmium selenide (CdSe) were made into inks and 3D printed into LEDs. These CdSe QDs of various sizes were prepared as colloidal suspensions (dispersed in a solvent) and printed onto the surfaces of planar and 3D shapes, resulting in a 3D electronic cube of multi-colored LEDs embedded within 3D printed silicone.

While silicon is the second-most abundant element on Earth and the primary driver of the semiconductor industry in recent decades, incorporating silicon-based optoelectronics on those chips is infeasible; since silicon has an indirect bandgap, bulk silicon emits heat, rather than light. Enter quantum mechanics: below 5 nm, instead of heat, silicon nanocrystals (SiNCs) emit red-infrared light, which we recently demonstrated with 3D printed LEDs – the first example of fully 3D printed silicon-based electronics. Importantly, silicon is biocompatible, so devices like these may have important applications in biomedical arenas.

Polymer photodiodes

These devices certainly have potential, but what about their performance? Do they meet the high standards of traditional semiconductors?

Unsurprisingly, we are at an early stage of development, so there’s a lot of work needed to reach those levels of performance. However, exciting early results suggest that fully 3D printed devices show substantial promise. The engineering challenge here is to optimize both the materials and the uniformity of the printed layers. It’s estimated that by precisely dispensing inks at desired locations, producing the devices using 3D printing can conserve over 90% of the materials compared to spin-coating. The tradeoff, though, is decreased layer uniformity, which arises from convection within the dispensed droplet during evaporation. By exploiting chemistry and fluid mechanics, such as utilizing co-solvents to optimize drying uniformity of the layers, photodiodes 3D printed with photoconductive polymers currently exhibit a photon-to-electron conversion efficiency of around 25%, a factor of only 2-4 less than microfabricated polymer-based photodiodes and commercial silicon photodetectors.

The conformal interface between electronics and biology

Monitoring a person’s health continuously provides a variety of benefits, but the bulky designs of current devices hinder their uptake. Indeed, discrepancies – flexibility and stretchability, for instance – in mechanical properties between electronics and human tissue can cause discomfort for the wearer. But what if we could get around that? What if we could conformally interface the device with the skin?

One potential solution for this is 3D printing, since:

- functional nanometer-scale materials can be produced as inks and dispensed in an additive, ‘bottom-up’ assembly process onto virtually any surface – including skin or irregular surfaces – under ambient conditions;

- 3D printing can merge functional materials such as silicon with softer biological materials on the same platform, overcoming mechanical discrepancies inherent to bulk semiconductor crystals;

- combining 3D scanning with 3D printing increases the anatomical accuracy when conformally integrating devices – be it onto the skin or within the body cavity – and the 3D printers can be made lightweight and portable.

Indeed, our group has developed an adaptive algorithm that, coupled with real-time scanning, incorporates computer vision into the printing process. We can fabricate devices on a moving surface, in real time, in a closed-loop fashion – even if the target is moving, freeform, or highly irregular. This is analogous to surgical robots, which suggests that printers are no longer just tools for dispensing inks, but rather, a type of robot that can merge with other robotic functions such as syringe injection, automation, and artificial intelligence through computer control. It suggests a new type of treatment paradigm, one where the printer is brought to the patient – rather than the patient to the printer – which significantly reduces lag time. These mobile 3D printers will be transported to the patient, and they will fabricate implantable biomedical devices or fresh cells directly onto skin wounds.

3D printing for ocular prosthetics: bionic eyes

“According to data from the 2017 National Health Interview Survey, 26.9 million American Adults age 18 and older reported experiencing vision loss” which can be caused by injury or degeneration of any part of the visual system. Degeneration of photoreceptors in the retina is a major cause of visual impairment, but because the human eye is a complex, spherically shaped imager, its capabilities are difficult to replicate despite sophisticated advances in high-resolution optoelectronics and biomaterial fabrication technologies. However, there have been several promising attempts to integrate electronics as a substitute for vision loss. The Argus II Retinal Prosthesis System, for example, is a surgically implanted antenna and electrode array that offers visual perception to retinitis pigmentosa patients.

Meanwhile, a self-powered, single pixel, fully organic photovoltaic (PV) prosthesis for subretinal implants has been demonstrated to treat degenerative blindness in a rat, showing recovery of light sensitivity and visual perception up to 10 months after implantation. Interestingly, the polymers used in this device are identical to the materials that we used in our own demonstrations.

3D printing presents a breadth of new possibilities when fabricating active electronics since the printing process works on a variety of surface shapes. Combining this ability with 3D scanning technologies, which can reconstruct a target surface into a digital rendering, we managed to print functional LEDs directly onto a contact lens. We also managed to print a hemispherical photodiode array directly onto a glass dome (see title image; video of the process can be found here). Curved photodiode arrays can effectively work as image sensors with wide viewing angles. Ultimately, they could lead to biomedical applications such as implantable bionic eyes.

Curved photodiode arrays can effectively work as image sensors with wide viewing angles. Ultimately, they could lead to biomedical applications such as implantable bionic eyes.

ide viewing angles. Ultimately, they could lead to biomedical applications such as implantable bionic eyes.

The customizable nature of 3D printing technologies enables researchers to explore opportunities to fabricate patient-specific healthcare devices. For example, during a Johnson & Johnson Vision Care business review meeting, analysts were told that “personalized contact lenses that can relieve eye allergies, reduce glare and eyestrain, and treat presbyopia are all concepts moving through the pipeline”.By using 3D scanning to measure eyeball shape, 3D printing could produce bespoke ophthalmic implants that individually fit the eye of the patient. Another interesting application of this technology is 3D printed contact lenses with embedded microneedle arrays, which can treat eye diseases such as macular degeneration by steadily releasing drugs while wearing.

Overall, 3D printing has emerged as a likely path toward the fabrication of next-generation optoelectronic devices and a promising new approach for making anatomically matched bio-electronic implants. By combining manufacturing engineering, materials development, computer control, bioengineering, and robotics, the 3D printing platform has become a cutting-edge tool that will undoubtedly play as ubiquitous a role in our lives as modern electronics.