Business is booming for iSolara, an Ottawa-based solar power design and installation company. Thanks to a government-sponsored tariff program, businesses, especially energy heavy farms in rural Ontario, are reaping the benefits of solar roof panels. But the design proposal process can take weeks to complete. iSolara is using 3D mapping software to streamline their proposal process, improve collaboration and reduce their design cycle by nearly 70%.

iSolara was launched in 2003 by engineer Warren Abar, with the belief that wide-scale adoption of solar energy is the best way to address climate change. The company is now the largest installer of net metered solar systems in Eastern Ontario, helping businesses find solar solutions that allow them to store their excess energy for later use. After trying their hand with other drones and software over the past few years, iSolara purchased a Phantom 4 last spring and began using DroneDeploy to help visualize, measure and design their largest projects.

Albert De Sousa is iSolara’s operation’s manager. He has fifteen years of project management experience and has been with the company since 2009. His current role includes project management, client and supplier coordination and of course, planning and executing drone flights. He shared a recent project in which DroneDeploy’s 3D mapping software helped the company provide better solar roof panel designs with a faster turnaround.

3D Mapping Software Replaces Satellite Imagery and Streamlines Design Workflow

Many of iSolara’s clients are farmers, ideal customers because they typically have high energy costs, combined with many outbuildings that can be fitted with solar panels. At the beginning of this year, the company began a project to design and install roof panels on a farmer’s calf barn. Thinking ahead, the farmer built the south-facing barn ten years ago with solar in mind. Recently, he requested a design proposal from iSolara.

To generate a solid proposal, the iSolara team must design a configuration of the solar panels in a given space and also estimate the amount of energy those panels will be able to harvest. In the past, this process generally took about two hours per building and was a dangerous process requiring workers to scale rooftops to make measurements needed to calculate an estimate. Afterward, the design team would set to work creating site plans and, using an in-house tool, generate an energy harvest estimate.

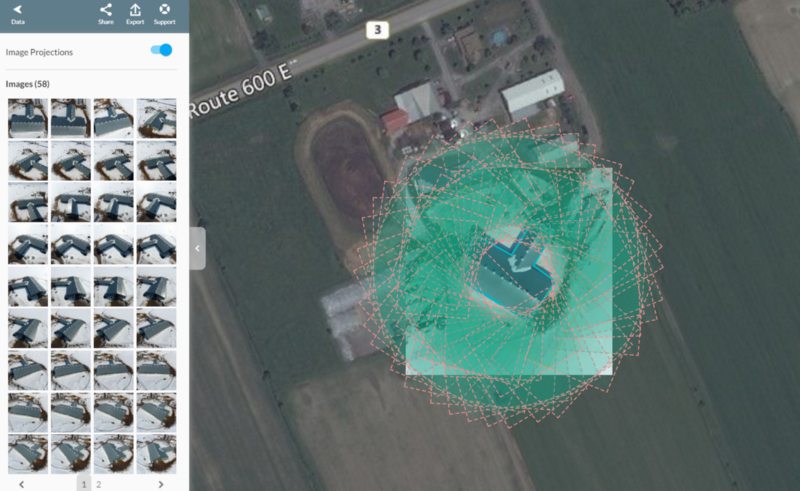

Whenever possible, the team would overlay plans onto existing satellite imagery to help visualize the designs. But in many rural locations, satellite images are often several years out of date and low quality.

With or without satellite imagery, the process still involves many moving parts. With designers, engineers and subcontractors all weighing in, the back and forth could take weeks and several rounds of designs.

“The sales process was painful. I realized there had to be a better way.” — Albert De Sousa, of the solar design proposal process before drones

Now, with projects like this cattle barn, a process that once began on a rooftop with a measuring tape, now begins with Albert firing up his Phantom 4.